SWF

Classification:

Key words:

News

SWF

FAQ

Details

Products

Inquiry

Case

FAQ

Under normal circumstances, it is not allowed. Above 60Hz (there are also modes above 50Hz), with constant voltage, it generally has a constant power characteristic. When the same torque is required at high speeds, attention must be paid to the selection of the motor and inverter capacity.

Power can still be output below 6Hz, but depending on conditions such as motor temperature rise and starting torque, the minimum operating frequency is set around 6Hz. At this point, the motor can output rated torque without causing serious heating issues. The actual output frequency (starting frequency) of the inverter varies by model, ranging from 0.5 to 3Hz.

When the frequency decreases, the voltage is reduced in direct proportion. Since the AC impedance decreases while the DC resistance remains unchanged, this will tend to reduce the starting torque at low speeds. Therefore, at low frequencies, to achieve a certain starting torque, the output voltage should be increased somewhat when V/f is given. This compensation is called enhanced starting. Various methods can be used to achieve this, including automatic methods, selecting V/f modes, or adjusting potentiometers.

When the frequency decreases, the voltage V also decreases proportionally. This issue has been explained in answer 4. The proportional relationship between V and f is predetermined considering the motor characteristics, and several characteristics are usually stored in the controller's storage device (ROM), which can be selected using a switch or a dial.

Using a frequency converter for operation, the frequency and voltage increase correspondingly with the acceleration of the motor, and the starting current is limited to below 150% of the rated current (depending on the model, it can be 125% to 200%). When starting directly with a power frequency supply, the starting current is 6 to 7 times higher, which can cause mechanical and electrical shocks. Using a frequency converter allows for a smooth start (the starting time is extended). The starting current is 1.2 to 1.5 times the rated current, and the starting torque is 70% to 120% of the rated torque; for frequency converters with automatic torque boost function, the starting torque can exceed 100%, allowing for full load starting.

When the frequency decreases (low speed), if the output power remains the same, the current increases, but under the condition of constant torque, the current remains almost unchanged.

The torque of the motor is generated by the interaction between the magnetic flux and the current flowing through the rotor. At the rated frequency, if the voltage is constant and only the frequency is reduced, the magnetic flux becomes too large, the magnetic circuit saturates, and in severe cases, it can burn out the motor. Therefore, the frequency and voltage must change proportionally, meaning that while changing the frequency, the output voltage of the inverter should be controlled to keep the magnetic flux of the motor constant, avoiding weak magnetism and magnetic saturation phenomena. This control method is often used in energy-saving variable frequency drives for fans and pumps.

The main circuit of the inverter can be roughly divided into two categories: the voltage type, which converts the DC of a voltage source into AC, with the filtering of the DC circuit done by capacitors; and the current type, which converts the DC of a current source into AC, with the filtering of the DC circuit done by inductors.

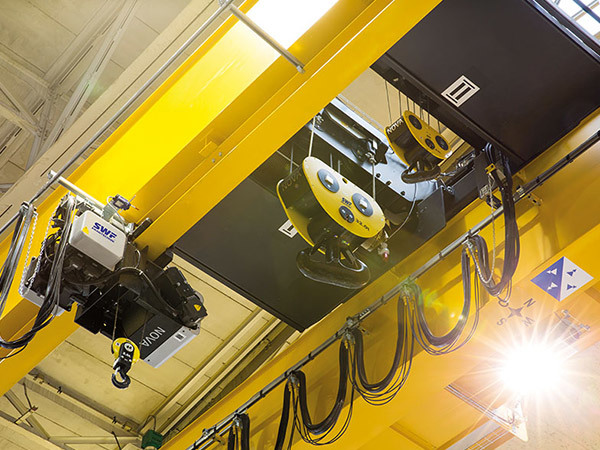

Product Introduction

The cooperation between SWF and Xingtai began in 2008, making SWF a reliable partner in the northern region.

Introduction to SWF:

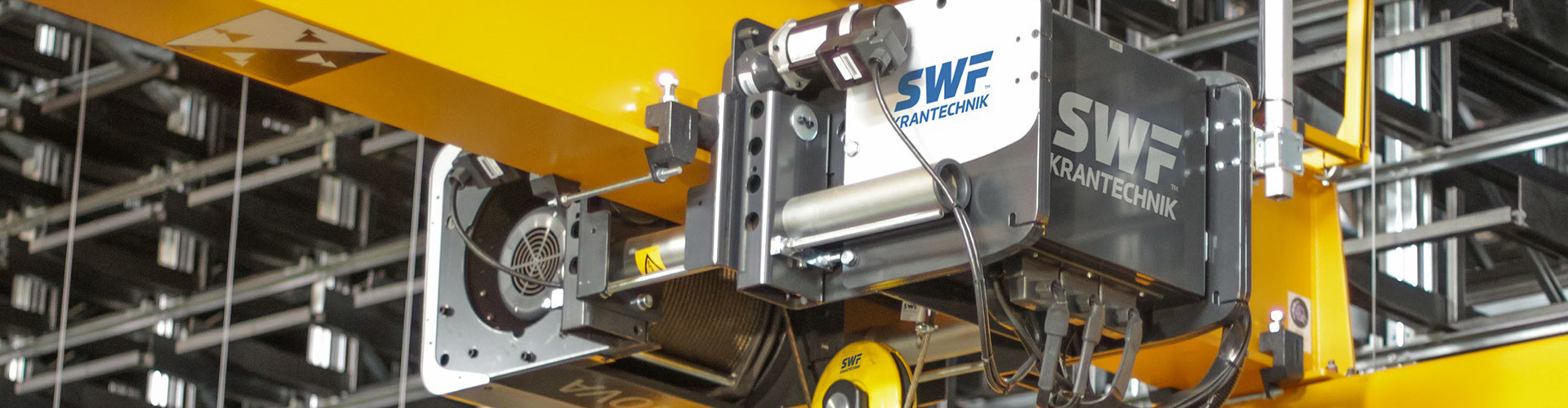

SWF is a leader in the global crane and lifting equipment industry. Founded in Germany in 1921, SWF has been known for providing high-quality lifting products ever since.SWF products are widely used in fields with extremely high performance and quality requirements.

There is a strong demand from automotive manufacturers for high-end lifting mechanisms, especially those with high reliability and quality requirements. Through cooperation with SWF, particularly in the area of wire rope hoists, we have fully met customers' needs for heavy-duty, high-frequency, and high working level lifting mechanisms, achieving a win-win-win situation for customer enterprises, SWF, and Xingtai. "SWF's wire rope electric hoists have gained a wide reputation among customers for their excellent quality."

In recent years, while continuously deepening its expertise in wire rope electric hoists, SWF has also been expanding and improving its original electric chain hoist product line, and has launched a more cost-effective black label series.

For more details about SWF, please see:http://www.swfkrantechnik.com/cn/about-us/welcome-to-swf.html

Previous Page:

Next page:

Online Inquiry

Fill in your phone number and E-mail information, and we will contact you as soon as possible.

Case

Leave your needs here.

Please leave your needs and we will contact you as soon as possible!

Service Hotline

Manufacturing address:intersection of Caibin West Street and Deren Road in Changchun China-Korea (Changchun) International Cooperation Demonstration Zone

Service Address:No.3 Fumin Street, Lvyuan District, Changchun City

Website:www.兴泰起重.中国

www.crane-china.cc

WeChat service number: xingtaiqizhong

Zip Code:130012

Sales Advisory Phone:400-044-6608/13578886608WeChat Synchronization (Mr. Zhang)

After-sales service telephone:18343082566(Mr. Yu)/400-044-6608

Landline:0431-87096377

Fax:0431-87096377

Copyright:Changchun Xingtai Crane Machinery Co.,Ltd