LH type electric hoist double girder crane

Classification:

Key words:

FAQ

Details

Products

Inquiry

Case

FAQ

Under normal circumstances, it is not allowed. Above 60Hz (there are also modes above 50Hz), with constant voltage, it generally has a constant power characteristic. When the same torque is required at high speeds, attention must be paid to the selection of the motor and inverter capacity.

Power can still be output below 6Hz, but depending on conditions such as motor temperature rise and starting torque, the minimum operating frequency is set around 6Hz. At this point, the motor can output rated torque without causing serious heating issues. The actual output frequency (starting frequency) of the inverter varies by model, ranging from 0.5 to 3Hz.

When the frequency decreases, the voltage is reduced in direct proportion. Since the AC impedance decreases while the DC resistance remains unchanged, this will tend to reduce the starting torque at low speeds. Therefore, at low frequencies, to achieve a certain starting torque, the output voltage should be increased somewhat when V/f is given. This compensation is called enhanced starting. Various methods can be used to achieve this, including automatic methods, selecting V/f modes, or adjusting potentiometers.

When the frequency decreases, the voltage V also decreases proportionally. This issue has been explained in answer 4. The proportional relationship between V and f is predetermined considering the motor characteristics, and several characteristics are usually stored in the controller's storage device (ROM), which can be selected using a switch or a dial.

Using a frequency converter for operation, the frequency and voltage increase correspondingly with the acceleration of the motor, and the starting current is limited to below 150% of the rated current (depending on the model, it can be 125% to 200%). When starting directly with a power frequency supply, the starting current is 6 to 7 times higher, which can cause mechanical and electrical shocks. Using a frequency converter allows for a smooth start (the starting time is extended). The starting current is 1.2 to 1.5 times the rated current, and the starting torque is 70% to 120% of the rated torque; for frequency converters with automatic torque boost function, the starting torque can exceed 100%, allowing for full load starting.

When the frequency decreases (low speed), if the output power remains the same, the current increases, but under the condition of constant torque, the current remains almost unchanged.

The torque of the motor is generated by the interaction between the magnetic flux and the current flowing through the rotor. At the rated frequency, if the voltage is constant and only the frequency is reduced, the magnetic flux becomes too large, the magnetic circuit saturates, and in severe cases, it can burn out the motor. Therefore, the frequency and voltage must change proportionally, meaning that while changing the frequency, the output voltage of the inverter should be controlled to keep the magnetic flux of the motor constant, avoiding weak magnetism and magnetic saturation phenomena. This control method is often used in energy-saving variable frequency drives for fans and pumps.

The main circuit of the inverter can be roughly divided into two categories: the voltage type, which converts the DC of a voltage source into AC, with the filtering of the DC circuit done by capacitors; and the current type, which converts the DC of a current source into AC, with the filtering of the DC circuit done by inductors.

Product Introduction

Product Detailed Introduction:

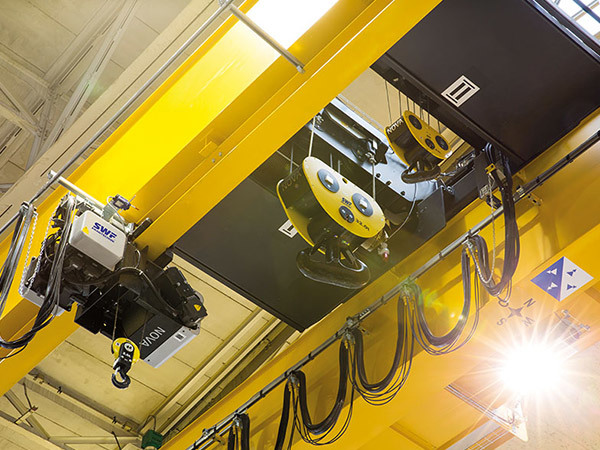

Every detail of the European-style double girder crane reflects Xingtai Cranes' pursuit of higher quality and technology.

The double girder bridge crane has an excellent weight/load ratio, and its geometric structure is designed reasonably to ensure the crane operates well while reducing wear. Since the hook can rise between the two main beams, it can significantly increase the lifting height. The control system can be operated manually, remotely, or from a cabin. As an optional item, a maintenance platform and a personnel trolley can also be added. This not only facilitates the maintenance of the crane but also allows maintenance personnel to safely reach other facilities in the workshop, such as lighting equipment, heating, or power lines.

Features and Advantages

◆ Excellent reliability design ensures efficient work.

◆ Lightweight, reducing investment costs.

◆ Optional maintenance platform and cabin control mode.

Common connection forms for 5-100 tons main and end beams

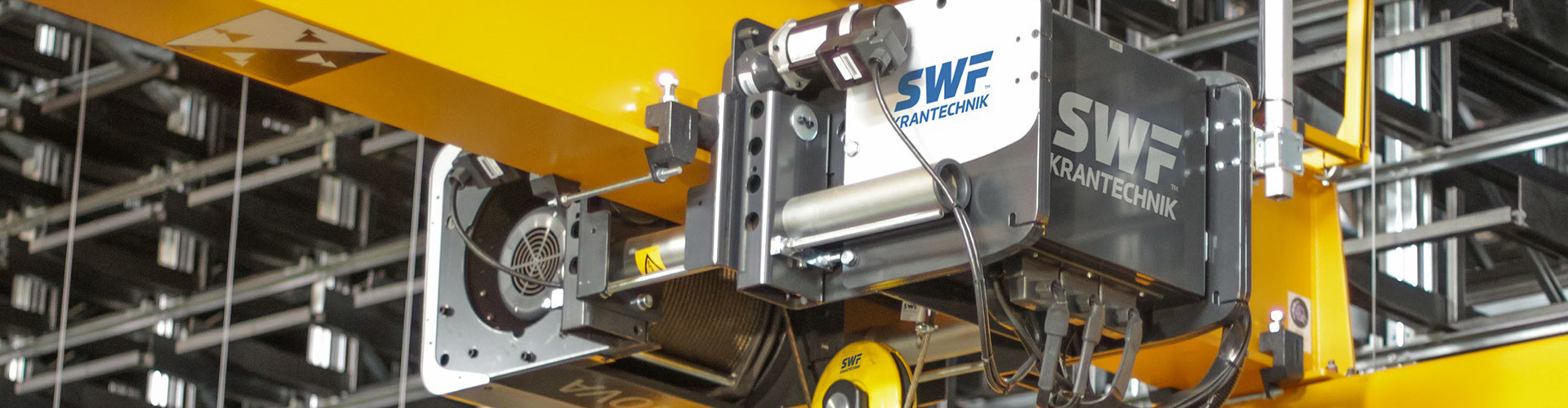

Power supply cable

◆ 4-7 cores, using bolt connections, ensuring long-term stable power supply and greatly reducing sudden shutdown situations.

◆ Pre-assembled parts facilitate the installation and replacement of components, such as replacing relays or installing straight rails.

◆ Protection level is IP23 or IP24, with sealed joints and integrated expansion compensation ensuring safety and preventing accidents.

Lower pulley

◆ The new lower pulley is very convenient to use with standard hooks.

◆ The rope guiding device prevents the steel wire rope and pulley groove from getting stuck.

Control System

◆ Ergonomically designed for safe use, comfortable grip, fatigue-resistant, and can display operating information in real-time. The fieldbus safety level is 3, complying with DIN/EN954 standards.

End Beam

◆ Box-type design, precisely connected with the main beam, improving structural rigidity, enhancing operational performance, and reducing wear.

◆ The interchangeability of components allows for precise arrangement and adjustment of wheels according to the crane's span, ensuring operational performance and adaptability.

◆ The crane's walking mechanism is designed using a dedicated static design program, making installation simple and use safe and efficient.

Walking Mechanism

◆ Compact "three-in-one" motor design changes the traditional planar decomposition layout to a three-dimensional integrated layout; wear-resistant self-aligning bearings allow it to withstand horizontal forces; wheels are made of cast steel alloy, improving operational performance and reducing wear on the track.

◆ The operating speed uses frequency control, with a maximum speed of 80 meters/min (no additional cables required), minimal sway, precise positioning, effectively reducing load.

Trolley

◆ The trolley frame structure has changed from the traditional four-beam planar structure to a three-beam flexible three-dimensional structure, achieving generalization; the hook pulley has an even double-row symmetrical structure, avoiding reverse bending of the steel wire rope.

◆ Compact structure, smaller hook limit position, and larger hook stroke can fully utilize every space in the workshop, improving the utilization rate of the workshop area and reducing costs.

Imported trolley attachments and additional equipment

Our additional devices cover a wide range, sufficient to meet users' various special requirements.

Previous Page:

Next page:

Online Inquiry

Fill in your phone number and E-mail information, and we will contact you as soon as possible.

Case

Leave your needs here.

Please leave your needs and we will contact you as soon as possible!

Service Hotline

Manufacturing address:intersection of Caibin West Street and Deren Road in Changchun China-Korea (Changchun) International Cooperation Demonstration Zone

Service Address:No.3 Fumin Street, Lvyuan District, Changchun City

Website:www.兴泰起重.中国

www.crane-china.cc

WeChat service number: xingtaiqizhong

Zip Code:130012

Sales Advisory Phone:400-044-6608/13578886608WeChat Synchronization (Mr. Zhang)

After-sales service telephone:18343082566(Mr. Yu)/400-044-6608

Landline:0431-87096377

Fax:0431-87096377

Copyright:Changchun Xingtai Crane Machinery Co.,Ltd