Number of views:

1011

Introduction to XW type monorail conveyor system

Retail price

0.0

元

Market price

0.0

元

Number of views:

1011

Product serial number

Category

XW

Quantity

-

+

Stock:

1

详细介绍

Product introduction:

The XW type monorail conveyor system is a patented product of our company. It has been widely used by companies such as FAW Jilin Automobile Co.,LTD and Sany Heavy Industry (Shenyang). Welcome to consult.

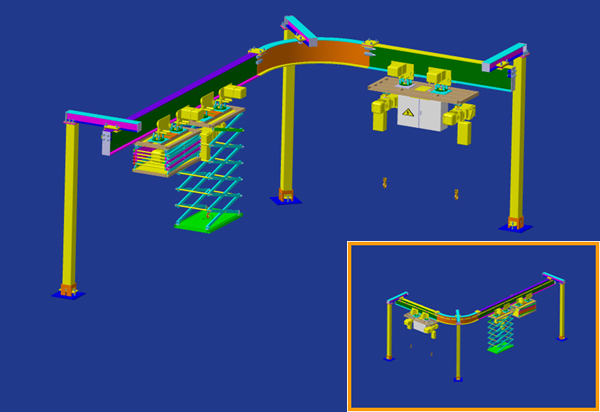

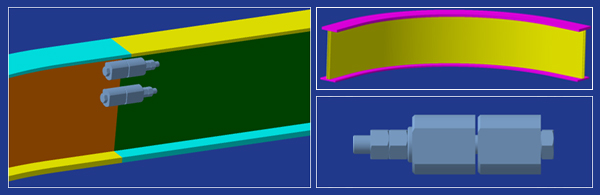

The XW type monorail conveyor system is made by matching the box-shaped curved rail invented by our company with the KITO electric chain hoist, which is especially suitable for automated production lines. Compared with the traditional I-beam, the box-shaped curved rail with the advantages of high wear-resistance and good stability has been widely praised by customers in use.

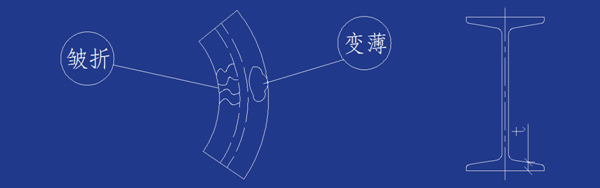

Analysis of the causes of severe wear on the monorail track curve

Assembly lines and logistics companies often use electric hoist monorail trolleys as small and medium-sized lifting equipment to achieve material movement. The rail of a monorail trolley is usually made of ordinary hot-rolled I-beam. The wear-resistance of such profiles is poor, and the rail wear is more serious when used frequently, especially the curved portion of the rail. In addition to the low strength and hardness of the rail Q235 itself, the main reason is the plastic deformation of the curved part during the forming process (The outer edge is thinned or even torn in tension, and the inner edge is pressed or even wrinkled).

The plastic deformation of the curved part during the forming process results in:

- With the increase of the longitudinal pressure on the free edge of the lower flange, the free edge becomes thinner and thinner until it is curled and scrapped.

- The inner edge of the arc is pressed to produce wrinkles, which makes the hoist trolley run unevenly, causing jitter (impact);

- The thickness of both sides of the lower flange is not uniform, causing the hoist trolley to tilt, resulting in uneven wheel pressure distribution.

The above problems are all important reasons for the partial wear of the track curve.

A solution to improve the wear of the monorail curve

- Change the Q235 ordinary hot-rolled I-beam to Q345 welded box-shaped rail with high strength and high wear-resistance.

- The CNC profiling cutting belt is used instead of hot or cold bending so that the above defects are not caused by plastic deformation during the processing.

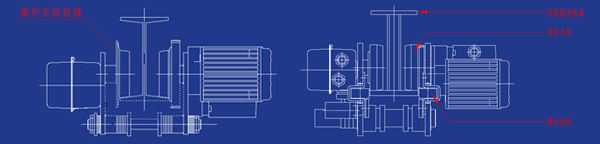

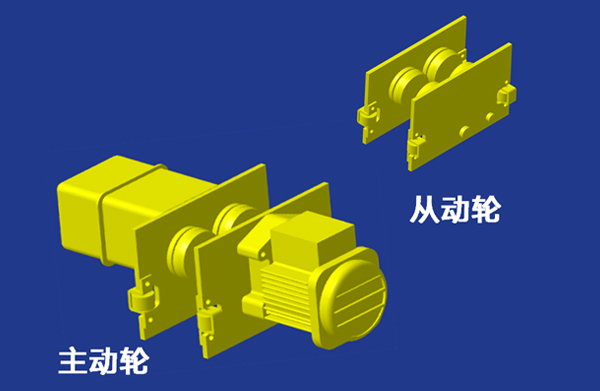

- The rail is changed from ordinary I-beam to welded box-shaped rail, and the flange is changed from a inclined plane to a flat plane. The drum-shaped wheel is used instead of the conical wheel to adapt to travelling on curve rail, ensuring that the wheel maintains a pure rolling state while running in the curved part.

- Replace the flange of the cone wheel with two sets of anti-wheels to reduce friction.

Technical realization:

Box-shaped rail and its components

- In terms of materials, the I-beam is made of Q235, which has poor wear resistance, while the box-shaped rail is made of Q345 (16Mn), which is low-alloy high-strength structural steel has high wear resistance.

- In terms of structure, the I-beam flange plate is thin and extremely easy to wear. When the wear reaches a certain level, the mechanical properties of the metal material are greatly reduced, resulting in the replacement of the rail in 1~2 years. The thickness of the flange plate of the box-shaped rail can be thickened with the increase of the load, and its wear resistance is strong, so the wear amount is small, and its service life is greatly extended.

- From the mechanical point of view, compared with the I-beam, the inertia distance of the X-axis and the Y-axis of the bo-shapedx rail is greatly increased, the deformation amount is reduced, and the stability is good. According to these characteristics, it is possible to reduce the support or suspend point in the straight line segment, leaving room for the site layout.

Box-shaped rail and its components

connection:

Fixture positioning is used to ensure coaxiality and components is connected by bolts.

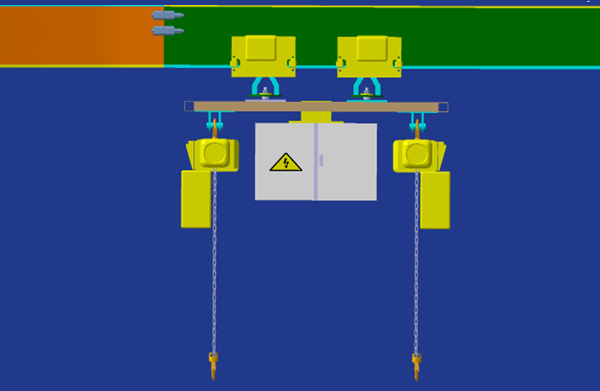

Single electric hoist

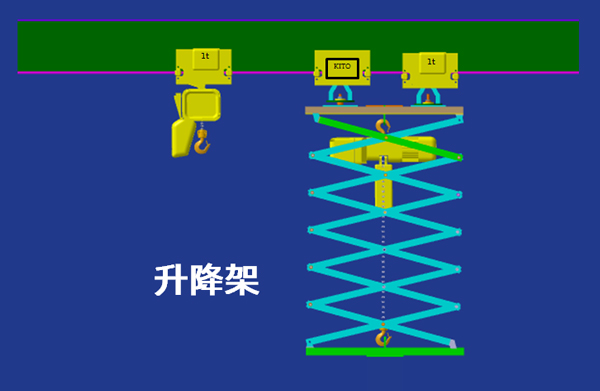

Single electric hoist with double trolleies

Double electric hoist

Field use

The XW type monorail conveyor system developed and produced by our company has been put into use in enterprises such as FAW Jilin Automobile. The hoist trolley runs smoothly on the box-shaped rail, the wear condition of the curved rail is obviously improved, and the service life is significantly improved in use.

Scan the QR code to read on your phone

Previous

None

Mobile

Changchun Xingtai Cranes Co., Ltd.

Add(production): Cross of Jvde Street and Dexian Road, Changde New District

Add(Installation&serviece): No. 3, Fumin Street, Lvyuan District, Changchun City

Website:www.兴泰起重.中国 www.crane-china.cc

WeChat service platform:xingtaiqizhong

Zip:130012

Sale hotline:400-044-6608 / 13578886608 (WeChat) (Mr. Zhang)

Service hotline:18343082566(Mr. Yu)/ 400-044-6608

Fixed line:0431-87095377

Fax:0431-87096377

Copyright 2019 All Rights Reserved.Xingtai Cranes 吉ICP备16002243号 by300.cn